MAA JANKI WORK SHOP

CAR WHEEL BALANCER WITH TOUCHSCREEN MONITOR AND NON-CONTACT DATA ENTRY

PREMIUM SERVICE

PRODUCT DESCRIPTION

The wheel balancer for garages, car dealerships, tyre shops and premium workshops with high tyre service volume. With touchscreen monitor, automatic non-contact data entry and easyWeight pinpoint indicator light – An accurate, fast and easy solution to position adhesive weights on the wheel. The integrated wheel lift automatically lifts a wheel to the last preset height.

-

High-productivity wheel balancer

-

Rim scanner for

- automatic non-contact rim profiling

- automatic selection of balancing mode and weight position

- automatic acquisition of rim diameter and offset -

Smart Sonar for automatic non-contact acquisition of rim width

-

Touchscreen monitor with graphical user interface PLATINUM – fast and very intuitive

-

easyWeight: fast pinpoint bottom weight placement. Pinpoint laser light indicator to accurately position adhesive weights on the wheel

-

Alternative positioning of adhesive weights with the geodata® gauge arm

-

Torque-controlled Power Clamp device – fast and accurate clamping of the wheel

-

Stop-in-Position feature where the operator only has to touch the amount of unbalance on the screen and the wheel is automatically indexed to correction position

-

QuickBal for reduced measurement time:

Short start-stop cycle time: 4.5 seconds (15’’ rim) -

VPM measurement technique for uncompromised accuracy

-

Telescopic wheel guard – requiring no additional back space

-

New ergonomic weight tray

-

Rim lighting to facilitate application of the geodata gauge arm

-

Imbalance minimisation and optimisation programs

-

High capacity, wheels up to 42” of diameter and 70 kg of weight

-

Networking capability with the optional networking software

-

Compatible with asanetwork

-

Print-out with optional printer

-

BW4030 – the ultimate wheel lift for wheel balancers, integrated in the cabinet, operated by the balancer's logic, automatically lifting a wheel of the same set to the correct height and consequently improving centring and clamping of the wheel

It is a tool that allows equipment to be connected to a garage.

With the Maa Janki work shop all relevant information are made available at every workstation in the shop as all machines are connected to the commercial software.

EASYWEIGHT™

Pinpoint laser identifies exact weight placement location for increased accuracy and efficiency.

EASYALU™

Touch the rim with the geodata™ arm to enter the rim dimensions.

OVERSIZE SHAFT

The 225 mm length allows the use of stud-hole flanges and other accessories for almost every type of rim.

SMART SONAR™

Automatic, non-contact rim width acquisition delivers greater accuracy and ease of use for a 30% savings in complete process when compared to manual operation.

PLATINUM USER INTERFACE

Highly intuitive and fast touch-screen monitor with large digits, coloured weight position indicators and PLATINUM user interface – improved intuitiveness and ergonomics.

RIM SCANNER

The rim scanner automatically detects rim diameter and offset as well as the number and position of rim spokes. Then it automatically chooses balancing mode, weight types and weight positions.

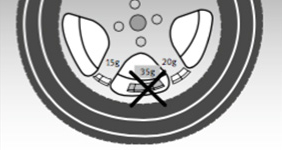

SPLIT WEIGHT MODE

Hides adhesive weights behind two adjacent spokes so they cannot be seen from the outside.

WHEEL GUARD

The patented and ergonomic telescopic wheel guard reduces the footprint.

WHEEL LIFT

The ultimate wheel lift for an easy and fast handling of wheels up to 70 kg. The wheel is automatically raised to the last centring height and the platform automatically returns to rest position, thus reducing floor-to-floor cycle time.

QUICKBAL™

30% reduced cycle time, less than 4,5 seconds, maintaining the same high accuracy.

VPM TECHNIQUE

Measurement system for high precision and repeatability.

POWER CLAMP™

Patented automatic Power Clamp™ electromechanical clamps the wheel accurately with a constant force, reducing the opportunity for chasing weight.

STOP IN POSITION

Touch the screen to automatically rotate the wheel to weight application position.